HEPA High Efficiency Air Filter

Material:HEPA filterFilter Type:

Car Fitment: /

Size: Customers\' Require

Color Customers\' Require

Package: Customized/Neutral

Filtration Efficiency: H13,H14

Sample: Avialable/Free

Place of Origin: CHINA

HEPA High Efficiency Air Filter

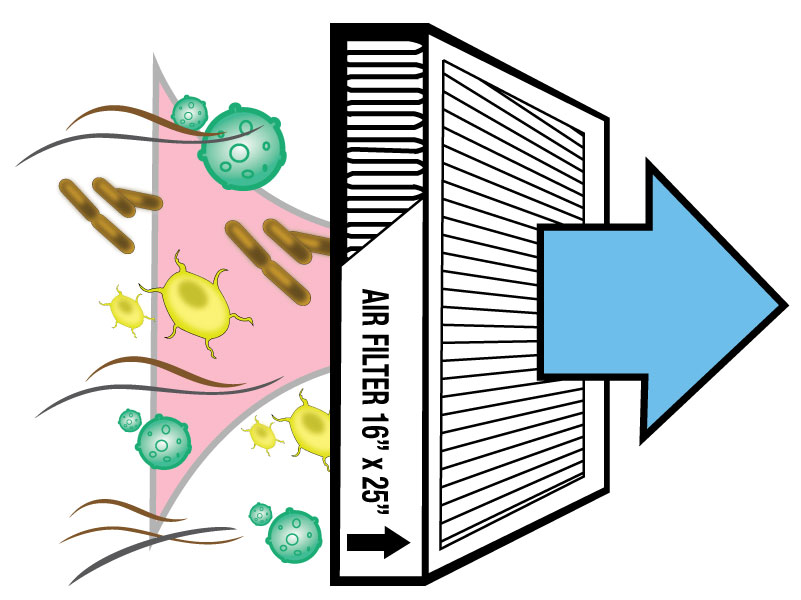

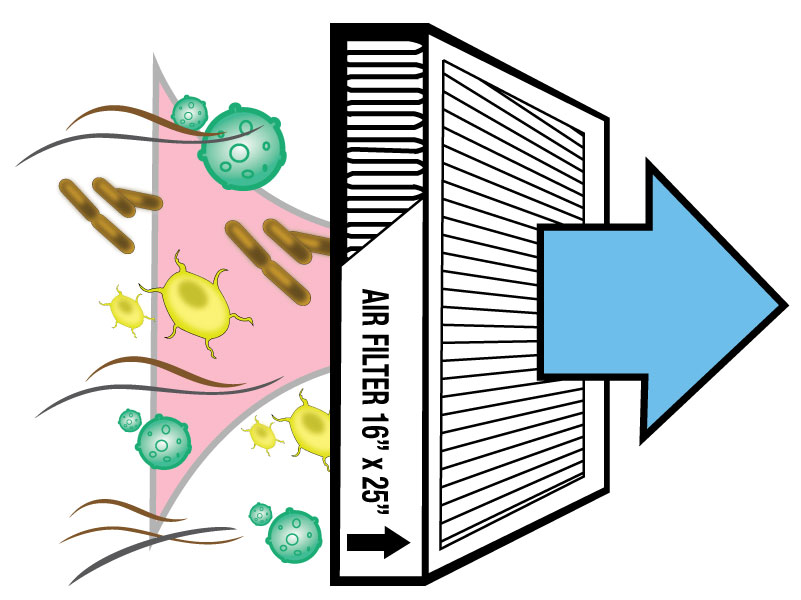

HEPA (High efficiency particulate air Filter), a filter that meets the HEPA standard, has an effective efficiency of 99.998% for 0.1 micron and 0.3 micron. The characteristic of the HEPA filter is that the air can pass, but the fine particles cannot pass.

Introduction to HEPA high efficiency air filter

The HEPA high efficiency air filter has a removal efficiency of more than 99.7% for particles with a diameter of 0.3 microns (1/200 of the hair diameter) and is the most effective filter medium for pollutants such as smoke, dust and bacteria. (The diameter of smoke particles produced by smoking is 0.5 microns)

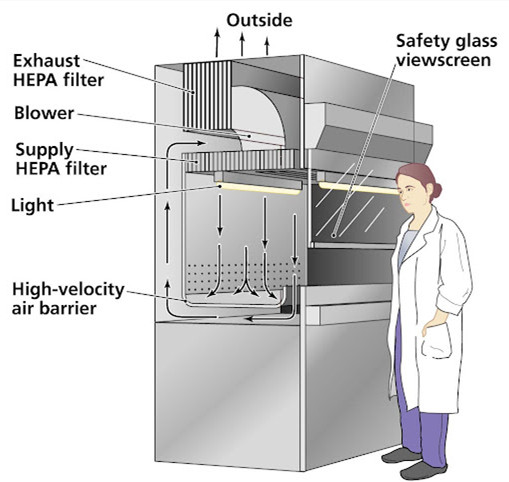

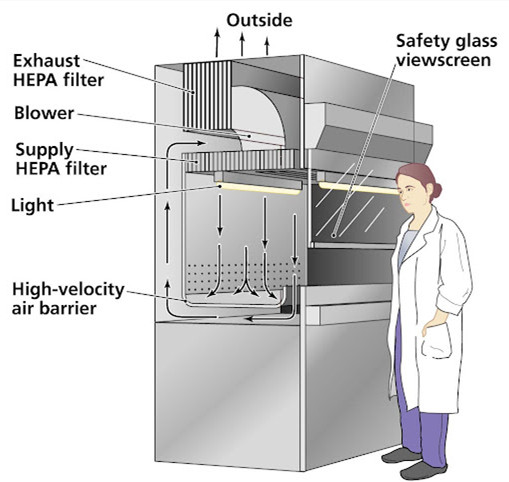

HEPA high efficiency air filter is recognized internationally as the most efficient filter material. It is often widely used in high-clean places such as operating rooms, animal laboratories, crystal experiments and aviation.

Application

HEPA high-efficiency filter can be widely used in the air supply at the end of the air conditioner in the dust-free purification workshop of industries such as optical electronics, LCD liquid crystal manufacturing, biomedicine, precision instruments, beverages and food, and PCB printing. High-efficiency and ultra-HEPA high-efficiency filters are used at the end of the clean room. According to their structure, they can be divided into: high efficiency with partitions, high efficiency without partitions, high-efficiency large air volume, and ultra-HEPA high-efficiency filters.

In addition, there are three kinds of HEPA high-efficiency filters, one is the ultra-HEPA high-efficiency filter, which can purify 99.9995%. One is the antibacterial high-efficiency air filter without partitions, which has antibacterial effect and prevents bacteria from entering the clean workshop, and the other is the sub-HEPA high-efficiency filter, which is cheap and used to purify spaces with low requirements.

HEPA is divided into five materials: PP filter paper, glass fiber, composite PP PET filter paper, melt-blown polyester non-woven fabric and melt-blown glass fiber. Features: large wind resistance, large dust holding capacity, high filtration accuracy, can be processed into various sizes and shapes according to customer needs, suitable for different models.

Features

1. Unique seamless sealing technology, better sealing effect, longer lasting, and not easy to leak;

2. The filter material has a metal protective net on both sides.

3. Various thicknesses such as 50mm, 69mm, 90mm, etc. are available.

4. Laser scanning and counting MPPS efficiency one by one: 95%-99.999995% (EN1882).

5. Filter grade: H11-H14, U15, U16 (EN1882).

Performance characteristics

◆The filtration efficiency for particles ≥0.3μm is above 99.97%

◆Using a computer-controlled automatic folding machine system for glue spray folding, the folding height range can be steplessly adjusted between 22~96mm

◆Special glass fiber filter paper as filter material

◆Each filter has been strictly inspected

◆Using international standard size specifications

Install

1. The installation environment should be kept level, and arranged side by side according to the actual situation;

2. The equipment itself is lighter and easier to install;

3. The inlet and outlet pipes of the equipment are connected by standard flanges or screw threads, which are fixedly supported and cannot rely on the valve body for support;

4. A water pressure gauge should be installed on the water inlet pipe of the equipment to prevent the dirt in the water inlet pipe from being blocked;

5. When the equipment is running, flushing water needs to be discharged, so a floor drain or drainage ditch needs to be set;

6. The brine tank in the equipment should be as close as possible to the softening tank, the shorter the better;

7. The sewage pipe of the equipment should not exceed 5m, the outlet should not be higher than the valve body, and the fewer elbows, the better;

8. When necessary, install power distribution sockets on the wall near the equipment and install fuses.

HEPA

The evolution of the international HEPA high-efficiency filter testing standards can be seen. The testing methods of high-efficiency air filters mainly include sodium flame method, oil mist method, DOP method, fluorescence method and particle counting method.

(1) Sodium flame method

The sodium flame method originated in the United Kingdom in 1969, and was implemented in some European countries in the 1970s and 1990s. It is one of the current national standard methods in my country. Its test dust source is polydisperse phase sodium chloride salt fog, and the "quantity" is the brightness of the hydrogen flame when the salt fog burns. The salt water splashes under the agitation of compressed air, and after drying, it forms tiny salt crystal particles and enters the air duct. Samples are taken before and after the filter. The salt mist samples make the color of the hydrogen flame blue and increase the brightness. The air is judged by the brightness of the flame. The main testing instrument is a flame photometer. The relevant standards of the sodium flame method are: British BS3928-1969, European Eurovent 4/4, and China GB6165-85. This method can only detect with low sensitivity and cannot detect ultra-HEPA high-efficiency filters.

(2) Oil mist method

The oil mist law originated in Germany and was also implemented in China and the former Soviet Union. The test dust source is oil mist, and the "quantity" is the turbidity of the air containing oil mist. The turbidity difference of the gas samples before and after the filter is used to judge the filter efficiency of the oil mist particles. Germany stipulates the use of paraffin oil, and the particle size of the oil mist is 0.3~0.5μm. The Chinese standard stipulates that the average weight diameter of oil mist is 0.28~0.34μm, and there is no specific regulation on the type of oil. The relevant standards are: China GB6165-85, Germany DIN24184-1990. When the oil mist method detects the filter, it is easy to cause damage to the filter, and the value cannot be read directly, which wastes time. At present, the German oil mist law has become history. Germany first promulgated the national standard with counting method as the detection method in 1993. The European standard EN-1822 was formulated on the basis of the German standard. At present, only a few military-industrial units in our country use this method.

(3) DOP method

The DOP method originated in the United States in 1956 and has been adopted by many countries, as well as in Chinese national standards. This method was once the most commonly used method for testing HEPA filters in the world. Its test dust source is 0.3μm monodisperse dioctyl phthalate (DOP) droplets, also known as "hot DOP", and "quantity" is the degree of turbidity of the air containing DOP. The DOP liquid is heated into steam, and the steam condenses into tiny droplets under specific conditions. After removing the excessively large and small droplets, particles of about 0.3 µm are left, which enter the air duct and measure the turbidity of the gas sample before and after the filter. , And judge the filter efficiency of 0.3μm dust. The measuring instrument is mainly a light scattering photometer. Related standards are: MIL-STD-282-1956.

(4) Fluorescence method

The fluorescence method is only used in France, and the test dust source of the fluorescence method is the fluorescein sodium dust produced by the sprayer. The test method is to first sample before and after the filter, then dissolve the sodium fluorescein on the sampling filter paper with water, and then measure the fluorescence brightness of the sodium fluorescein aqueous solution under specific conditions. The brightness reflects the weight of the dust, and the filter’s filtration is calculated. efficient. Fluorescence method is no longer used in France, and they have statutory the counting of European Standards Association as a national standard. At present, some nuclear industry system field detection filters also use fluorescence method.

(5) Particle counting method

This method is commonly used in Europe, and the U.S. Ultra HEPA high efficiency filter test method is also relatively similar, and it is currently the mainstream test method in the world. The dust source is polydisperse phase droplets, or solid dust with a certain particle size. Sometimes, filter manufacturers have to use atmospheric dust or other specific dust in accordance with the special requirements of users. If a condensation nucleus counter is used in the test, a monodisperse test dust source with a known particle size must be used. The main measuring instrument is a large-flow laser particle counter or a condensation nucleus counter (CNC). Scan and inspect the entire air outlet surface of the filter with a counter. The counter gives the number of dust at each point, and can also compare the local efficiency of each point.

European experience shows that for HEPA filters, the most easily penetrated dust particle size is between 0.1μm and 0.25μm. First determine the test conditions for the most easily penetrated dust particle size, and then continuously scan and measure the filter. For the filter effect of this particle size dust, Europeans call this method the MPPS method [14]. The American standard stipulates that only particles in the range of 0.1~0.2μm are measured. The MPPS method is actually a particle counting method, because the detection instrument used is a particle counter or a condensation nucleus particle counter. The relevant standards of this method are: European EN1882-1998~2000, American IES-RP-CC007.1-1992.

HEPA (High efficiency particulate air Filter), a filter that meets the HEPA standard, has an effective efficiency of 99.998% for 0.1 micron and 0.3 micron. The characteristic of the HEPA filter is that the air can pass, but the fine particles cannot pass.

Introduction to HEPA high efficiency air filter

The HEPA high efficiency air filter has a removal efficiency of more than 99.7% for particles with a diameter of 0.3 microns (1/200 of the hair diameter) and is the most effective filter medium for pollutants such as smoke, dust and bacteria. (The diameter of smoke particles produced by smoking is 0.5 microns)

HEPA high efficiency air filter is recognized internationally as the most efficient filter material. It is often widely used in high-clean places such as operating rooms, animal laboratories, crystal experiments and aviation.

Application

HEPA high-efficiency filter can be widely used in the air supply at the end of the air conditioner in the dust-free purification workshop of industries such as optical electronics, LCD liquid crystal manufacturing, biomedicine, precision instruments, beverages and food, and PCB printing. High-efficiency and ultra-HEPA high-efficiency filters are used at the end of the clean room. According to their structure, they can be divided into: high efficiency with partitions, high efficiency without partitions, high-efficiency large air volume, and ultra-HEPA high-efficiency filters.

In addition, there are three kinds of HEPA high-efficiency filters, one is the ultra-HEPA high-efficiency filter, which can purify 99.9995%. One is the antibacterial high-efficiency air filter without partitions, which has antibacterial effect and prevents bacteria from entering the clean workshop, and the other is the sub-HEPA high-efficiency filter, which is cheap and used to purify spaces with low requirements.

HEPA is divided into five materials: PP filter paper, glass fiber, composite PP PET filter paper, melt-blown polyester non-woven fabric and melt-blown glass fiber. Features: large wind resistance, large dust holding capacity, high filtration accuracy, can be processed into various sizes and shapes according to customer needs, suitable for different models.

Features

1. Unique seamless sealing technology, better sealing effect, longer lasting, and not easy to leak;

2. The filter material has a metal protective net on both sides.

3. Various thicknesses such as 50mm, 69mm, 90mm, etc. are available.

4. Laser scanning and counting MPPS efficiency one by one: 95%-99.999995% (EN1882).

5. Filter grade: H11-H14, U15, U16 (EN1882).

|

Standard sizes W×H×Dmm |

Rated air volume m/h |

Filter area (m) |

Dust holding capacity (g) |

Initial resistance (Face wind speed 0.5m/s) |

Final resistance | Filtration efficiency |

| 305×305×50 | 200 | 1.8 | 100 | ≤220Pa | 400Pa |

99.99% or more H13-H14 |

| 484×484×50 | 500 | 4.6 | 300 | ≤220Pa | 400Pa | |

| 610×610×50 | 800 | 7.5 | 450 | ≤220Pa | 400Pa | |

| 915×610×50 | 1200 | 11.2 | 700 | ≤220Pa | 400Pa | |

| 1220×610×50 | 1600 | 14.9 | 900 | ≤220Pa | 400Pa | |

| 305×305×69 | 260 | 2.5 | 150 | ≤220Pa | 400Pa | |

| 484×484×69 | 700 | 6.6 | 400 | ≤220Pa | 400Pa | |

| 610×610×69 | 1100 | 10.7 | 650 | ≤220Pa | 400Pa | |

| 915×610×69 | 1600 | 16.0 | 950 | ≤220Pa | 400Pa | |

| 1220×610×69 | 2200 | 21.3 | 1000 | ≤220Pa | 400Pa | |

| 610×610×90 | 1500 | 14.9 | 900 | ≤220Pa | 400Pa | |

| 915×610×90 | 2000 | 22.3 | 1200 | ≤220Pa | 400Pa | |

| 1220×610×90 | 2800 | 29.8 | 1800 | ≤220Pa | 400Pa |

Performance characteristics

◆The filtration efficiency for particles ≥0.3μm is above 99.97%

◆Using a computer-controlled automatic folding machine system for glue spray folding, the folding height range can be steplessly adjusted between 22~96mm

◆Special glass fiber filter paper as filter material

◆Each filter has been strictly inspected

◆Using international standard size specifications

Install

1. The installation environment should be kept level, and arranged side by side according to the actual situation;

2. The equipment itself is lighter and easier to install;

3. The inlet and outlet pipes of the equipment are connected by standard flanges or screw threads, which are fixedly supported and cannot rely on the valve body for support;

4. A water pressure gauge should be installed on the water inlet pipe of the equipment to prevent the dirt in the water inlet pipe from being blocked;

5. When the equipment is running, flushing water needs to be discharged, so a floor drain or drainage ditch needs to be set;

6. The brine tank in the equipment should be as close as possible to the softening tank, the shorter the better;

7. The sewage pipe of the equipment should not exceed 5m, the outlet should not be higher than the valve body, and the fewer elbows, the better;

8. When necessary, install power distribution sockets on the wall near the equipment and install fuses.

HEPA

The evolution of the international HEPA high-efficiency filter testing standards can be seen. The testing methods of high-efficiency air filters mainly include sodium flame method, oil mist method, DOP method, fluorescence method and particle counting method.

(1) Sodium flame method

The sodium flame method originated in the United Kingdom in 1969, and was implemented in some European countries in the 1970s and 1990s. It is one of the current national standard methods in my country. Its test dust source is polydisperse phase sodium chloride salt fog, and the "quantity" is the brightness of the hydrogen flame when the salt fog burns. The salt water splashes under the agitation of compressed air, and after drying, it forms tiny salt crystal particles and enters the air duct. Samples are taken before and after the filter. The salt mist samples make the color of the hydrogen flame blue and increase the brightness. The air is judged by the brightness of the flame. The main testing instrument is a flame photometer. The relevant standards of the sodium flame method are: British BS3928-1969, European Eurovent 4/4, and China GB6165-85. This method can only detect with low sensitivity and cannot detect ultra-HEPA high-efficiency filters.

(2) Oil mist method

The oil mist law originated in Germany and was also implemented in China and the former Soviet Union. The test dust source is oil mist, and the "quantity" is the turbidity of the air containing oil mist. The turbidity difference of the gas samples before and after the filter is used to judge the filter efficiency of the oil mist particles. Germany stipulates the use of paraffin oil, and the particle size of the oil mist is 0.3~0.5μm. The Chinese standard stipulates that the average weight diameter of oil mist is 0.28~0.34μm, and there is no specific regulation on the type of oil. The relevant standards are: China GB6165-85, Germany DIN24184-1990. When the oil mist method detects the filter, it is easy to cause damage to the filter, and the value cannot be read directly, which wastes time. At present, the German oil mist law has become history. Germany first promulgated the national standard with counting method as the detection method in 1993. The European standard EN-1822 was formulated on the basis of the German standard. At present, only a few military-industrial units in our country use this method.

(3) DOP method

The DOP method originated in the United States in 1956 and has been adopted by many countries, as well as in Chinese national standards. This method was once the most commonly used method for testing HEPA filters in the world. Its test dust source is 0.3μm monodisperse dioctyl phthalate (DOP) droplets, also known as "hot DOP", and "quantity" is the degree of turbidity of the air containing DOP. The DOP liquid is heated into steam, and the steam condenses into tiny droplets under specific conditions. After removing the excessively large and small droplets, particles of about 0.3 µm are left, which enter the air duct and measure the turbidity of the gas sample before and after the filter. , And judge the filter efficiency of 0.3μm dust. The measuring instrument is mainly a light scattering photometer. Related standards are: MIL-STD-282-1956.

(4) Fluorescence method

The fluorescence method is only used in France, and the test dust source of the fluorescence method is the fluorescein sodium dust produced by the sprayer. The test method is to first sample before and after the filter, then dissolve the sodium fluorescein on the sampling filter paper with water, and then measure the fluorescence brightness of the sodium fluorescein aqueous solution under specific conditions. The brightness reflects the weight of the dust, and the filter’s filtration is calculated. efficient. Fluorescence method is no longer used in France, and they have statutory the counting of European Standards Association as a national standard. At present, some nuclear industry system field detection filters also use fluorescence method.

(5) Particle counting method

This method is commonly used in Europe, and the U.S. Ultra HEPA high efficiency filter test method is also relatively similar, and it is currently the mainstream test method in the world. The dust source is polydisperse phase droplets, or solid dust with a certain particle size. Sometimes, filter manufacturers have to use atmospheric dust or other specific dust in accordance with the special requirements of users. If a condensation nucleus counter is used in the test, a monodisperse test dust source with a known particle size must be used. The main measuring instrument is a large-flow laser particle counter or a condensation nucleus counter (CNC). Scan and inspect the entire air outlet surface of the filter with a counter. The counter gives the number of dust at each point, and can also compare the local efficiency of each point.

European experience shows that for HEPA filters, the most easily penetrated dust particle size is between 0.1μm and 0.25μm. First determine the test conditions for the most easily penetrated dust particle size, and then continuously scan and measure the filter. For the filter effect of this particle size dust, Europeans call this method the MPPS method [14]. The American standard stipulates that only particles in the range of 0.1~0.2μm are measured. The MPPS method is actually a particle counting method, because the detection instrument used is a particle counter or a condensation nucleus particle counter. The relevant standards of this method are: European EN1882-1998~2000, American IES-RP-CC007.1-1992.

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.