- home > News > Filter knowledge

How to test the high efficiency air filter(HEPA)

How to test the high efficiency air filter(HEPA)

Five common leak detection methods for high efficiency air filters(HEPA)

HEPA filters are very popular in some special environments (such as clean rooms, laboratories, operating rooms, etc.) due to their high filtration efficiency. Although the filtration efficiency of the high-efficiency filter is high, the installation requirements are also very strict, and leak detection must be carried out, otherwise the rated filtration efficiency will not be achieved.

High-efficiency air filters(HEPA)are high-precision filtration equipment, and corresponding testing equipment is required to ensure product quality. Common leak detection methods are generally divided into five types. These five methods are: sodium flame method, oil mist method, DOP method, fluorescence method method and particle counting. Below, the editor of Suzhou Xingyuan Clean Environment Technology will explain to you five common leak detection methods and principles of high-efficiency filters.

1. Sodium flame method

Its test dust source is polydisperse sodium chloride salt spray, and the "quantity" is the brightness of the hydrogen flame when the salt spray is burned. The salt water splashes under the agitation of compressed air, and after drying, tiny salt crystal particles are formed and enter the air duct. Samples are taken before and after the filter. The salt mist gas sample makes the color of the hydrogen flame blue and the brightness increases. The brightness of the flame is used to judge the air. The concentration of salt spray can be used to determine the filtration efficiency of the filter for salt spray.

2. Oil mist method

The test dust source is oil mist, and the "amount" is the turbidity of the air containing oil mist. The turbidity difference between the gas samples before and after the high-efficiency air filter is used to judge the filtration efficiency of the filter for oil mist particles. When the oil mist method detects the filter, it is easy to cause damage to the filter, and the value cannot be directly read, which is a waste of time.

3. DOP method

This method used to be a common method for testing HEPA sponges. Its test dust source is a 0.3 micron monodisperse dioctyl phthalate (DOP) droplet, also known as "hot DOP", where "amount" is the degree of turbidity of the DOP-containing air. The DOP liquid is heated into steam, and the steam is condensed into tiny droplets under specific conditions. After removing the too large and too small droplets, the particles of about 0.3 microns are left, which enter the air duct and measure the turbidity of the gas sample before and after the filter. , and thus judge the filtration efficiency of the filter for 0.3 micron dust.

4. Fluorescence method

The test dust source of the fluorescence method is the sodium fluorescein dust generated by the sprayer. The test method is to first sample before and after the filter sponge, then dissolve the sodium fluorescein on the sampling filter paper with water, and then measure the fluorescence of the sodium fluorescein-containing aqueous solution under specific conditions. Brightness, the brightness reflects the weight of the dust, from which the filtering efficiency of the filter is calculated.

5. Particle counting method

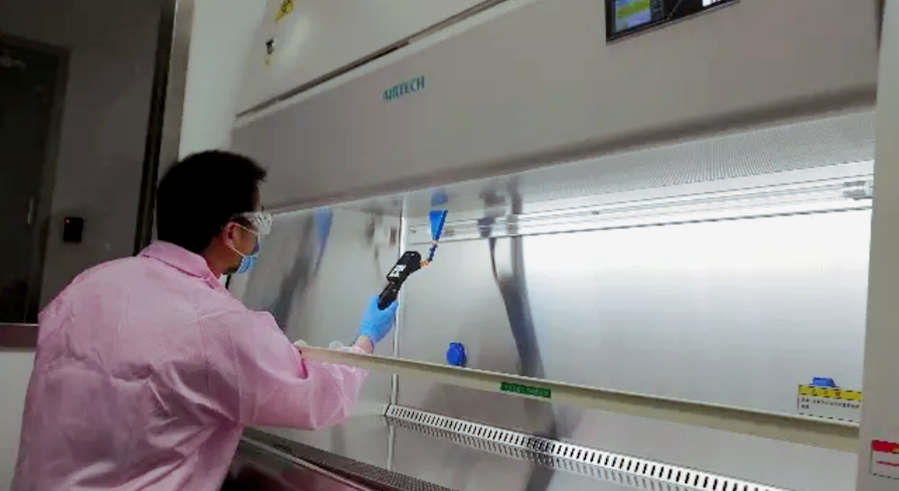

This method is the current mainstream sponge testing method. The dust source is polydisperse phase droplets, or solid dust of defined particle size. The main measuring instrument is a high-flow laser particle counter or a condensation nucleus counter (CNC). Use the counter to scan and inspect the entire air outlet surface of the high-efficiency air filter. The counter gives the number of dust at each point, and the local efficiency of each point can also be compared.

High-efficiency air filter(HEPA)leak detection, as one of the inspection items in clean workshops, has received more and more attention since the implementation of GMP in 2010.

It has now become a must-check item for pharmaceutical companies, and more and more units are conducting high-efficiency filter leak detection in hospitals, electronics, food, cosmetics and other industries.

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.